Minnesota and Western Wisconsin’s Quality HVAC Equipment Supplier

TMS Johnson is a full service, supplier of quality HVAC equipment and solutions to the contracting and engineering communities in Minnesota and Western Wisconsin.

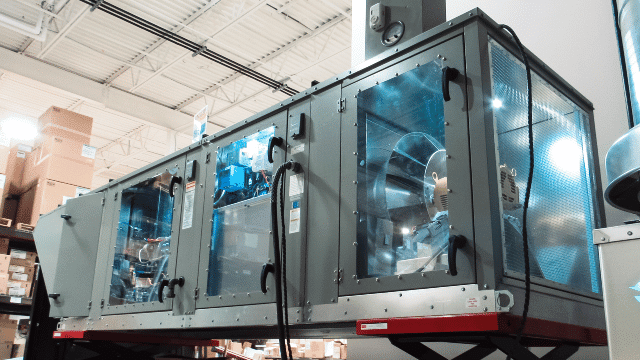

TMS Johnson prides itself in first class customer to meet the industry’s demanding needs. They provide quick response time by having a complete warehouse with products from the industries’ top manufacturers, such as Greenheck, Price and LG, just to name a few.

Believers in continuous education in an ever-changing industry, TMS Johnson also has a learning and training center where they provide the latest information to engineers and contractors throughout the region.

TMS Johnson Learning Center

Our new learning center is located on our campus at 2908 Nevada Avenue N in New Hope, Minnesota. If you have questions about our training opportunities or would like to tour the learning center, please email Andrea Lind or call 763-544-5442. We look forward to hosting you at an upcoming training.

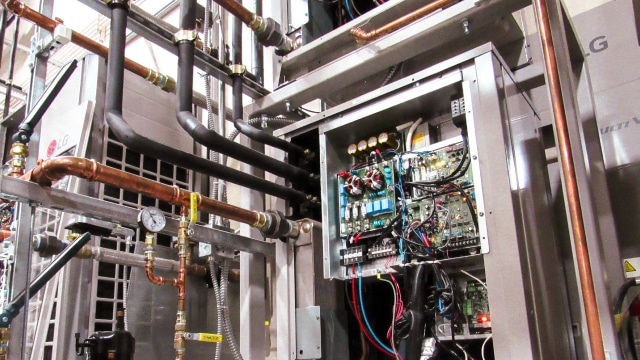

MLV-03 Multi V™ Advanced Service

and Troubleshooting

Available By Request

2 Days, 8 Hours Each Day

Become familiar with the breadth of LG’s main and sub PCBs and learn the part each component plays in a correctly operating LG Multi V™ system. We’ll cover indoor and outdoor electrical connections, all major functional components, service and maintenance guidance, and more.